Four-channel RGB driver board using a

Teensy 3.1

(Last modified

24 Apr 2015)

I ran into a true Renaissance man last year at an art festival

in Bellevue, WA. His name is Sam Bates and he does (among MANY

other things) staggeringly beautiful hand-carved sheet-glass sculptures

(check this

out!). I spent an hour or so talking with Sam about his

artwork. Many of his displayed pieces used side-lighting with RGB

LEDs. The effect is gorgeous, but Sam is a true perfectionist and

mentioned a couple of issues with the off-the-shelf DMX-512 controllers

he was using.

The main problem was the step resolution of the color changes.

Often, when setting up the colors he wanted, Sam found that a one-step

change in red, for instance, gave him too much red or not enough; he

couldn't hit the exact shade he wanted. This step-resolution

issue also caused problems in fades to black. At the end of the

fade, there would be a small time where only one color would be

visible; the other colors had switched off because there was no smaller

step interval. This showed as a jarring color blink just before

black.

Another problem Sam faced dealt with color brightness at lower

levels. Basically, setting the color values in the software to

half-scale did not produce half brightness; the brightness was only

slightly reduced from full-on. But the mid- to lower-brightness

levels are where the subtle color play should happen, and the

controller Sam was using simply wasn't giving him the control he wanted.

After hearing what he really wanted in the perfect RGB driver, I told

him writing the proper firmware would be

trivial. He got really excited, we spent some time discussing

design issues, and I headed back to my lab with a new project.

I needed to design a MOSFET-based RGB driver board capable of driving

up to four strips of RGB LEDs. The driver firmware needed to

support:

- Much finer resolution than the 256 steps Sam was currently using

- Better brightness linearity

- Multiple scenes (a scene is a group of RGB settings for each of

the four strips)

- Fades and switches between scenes

- Simple user interface for adjusting any single color and for

setting up scenes

- Relatively cheap

- Built around easy to get parts

I decided to go with a Teensy 3.1 as the micro. The T31 is about

$20, provides a bunch of memory, has a dozen hardware-based PWM

channels, and I already have a lot of support code written for some of

the subsystems I'll be using.

Note that the final project is not yet done; some of the user interface

features in the list above still need to be added. But the

electronics and supporting firmware for many of the basic features are

done and the project is ready to hook up to a glass piece.

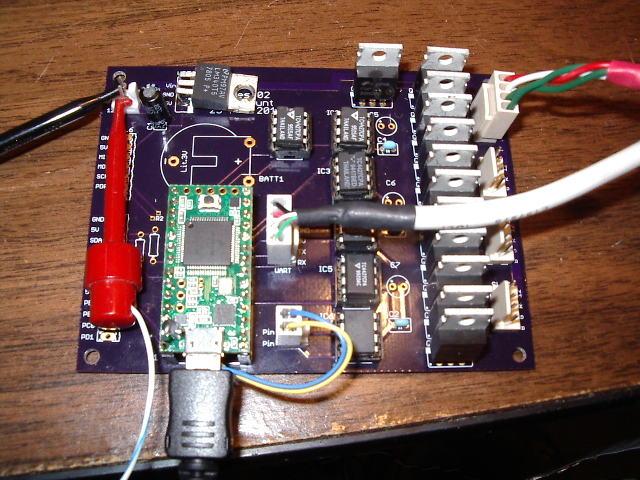

Here you see the board with all 12 power MOSFETs installed. The

Teensy 3.1 board is the green daughter board in the lower left.

The blue and yellow wires from the white 2-pin connector next to the

Teensy carry two PWM signals from solder pads on the underside of the

Teensy board.

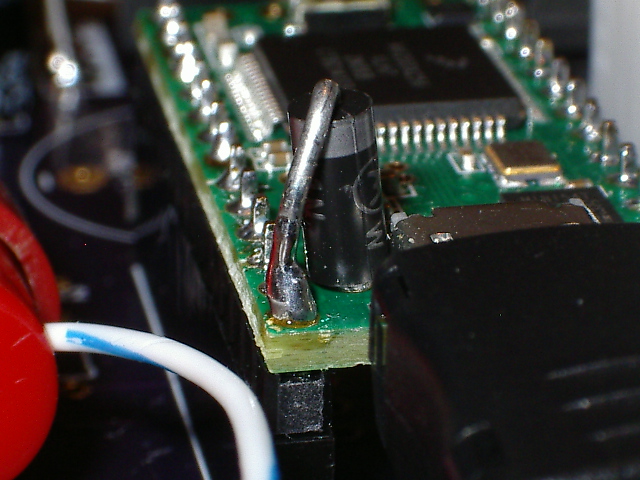

Here is the added Schottky diode, mounted next to the USB connector on

the Teensy board. The lower lead of the diode fits in an

unpopulated via labeled VUSB on the underside of the Teensy

board. Make sure you install the diode with the cathode (banded)

lead away from the board.

Teensy 3.1 PWM

The Teensy 3.1 board supports, with a bit of extra soldering, 12

hardware-generated PWM channels. Ten of these channels appear on

the standard 28 pins along the Teensy's two longer edges. The

last two PWM outputs appear on solder pads on the underside of the

Teensy's PWB. Here is a list of the available PWM outputs, taken

from comments in my driver program:

Signal

FTM Dev pin

Teensy pin

------

--- -------

----------

RED.0

0:0 PTC1

22

GRN.0

0:1 PTC2

23

BLU.0

0:2 PTC3

9

RED.1

0:3 PTC4

10

GRN.1

0:4 PTD4

6

BLU.1

0:5 PTD5

20

RED.2 0:6

PTD6 21

GRN.2

0:7 PTD7

5

BLU.2

1:0 PTA12

3

RED.3 1:1

PTA13 4

GRN.3

2:0 PTB18

32

BLU.3

2:1 PTB19

25

The Teensy 3.1 uses a Freescale MK20DX256 device, which contains three

Flexible Timer Modules (FTMs) for hardware-generated PWM, among other

timing capabilities. The column above labeled FTM defines the FTM

module and channel used to drive a color. For example, the red

drive for the first RGB strip (RED.0) comes from channel 0 of FTM

module 0. The entry in the Dev pin column shows this signal

appears on the MK20 MCU as port C, bit 1, and on the T31 board as pin

22.

Note that the last two channels, for GRN.3 and BLU.3, appear on the T31

as pins 32 and 25. These are actually solder pads on the

underside of the T31 board.

The schematic

Here is the schematic for the first draft

of this project (PDF).

I was not happy with the results I got when driving the MOSFETs

directly from the T31's PWM outputs. I am using a PWM frequency

of over 4 kHz;.at that frequency, the gate capacitance of the

MOSFETs caused issues with the drive signal quality. I opted to

run the PWM outputs into some dual-channel 4427 MOSFET drivers, then

let the 4427s drive the MOSFETs.

This decision offers a side benefit. If you will be driving less

than 750 mA of LEDs per channel, you can replace each MOSFET with a

ware between gate and source. This effectively lets the 4427s

drive the LEDs directly. Unfortunately, I chose the 4427 because

I had a bunch of them laying around. The 4426 is a better choice,

since it includes a built-in inversion between the drive signal and the

output. If the board is populated with 4427s and you want to

drive the LEDs directly, you need to set a flag in the code to invert

the PWM drive signal. If the board is populated with 4426s, which

have the same pinout, you should not need to invert the drive signal in

the code. Note that I haven't tested this yet...

The schematic includes several connectors not needed to meet Sam's

requirements. I added access to the I2C bus, an SPI channel, RTC

battery, and some GPIO and A/D pins because they might come in handy

for other projects. All I need to support Sam's current

requirements are SL4 (serial port), 12 VDC input, and the 4427s and

MOSFETs.

Modify the Teensy 3.1 for external

power

Note that you must modify the T31 board before you can drive it from

external power. The PJRC website includes details for modifying

other Teensy boards; see here for

example. The mod I did to my T31 board is very similar. You

will need one 1N5817 Schottky diode with axial leads (not SMD).

First, isolate the USB 5 VDC from the rest of the circuit by cutting a

trace on the underside of the board, between two large pads near the

VUSB pin; see back of the Teensy 3.1 reference card for details.

Next, insert the anode lead (end WITHOUT the stripe) of the Schottky

diode into the hole marked VUSB. Note that the body of the diode

should be on the top side of the board; refer to my photos.

Solder this lead in place, then trim the excess lead.

Finally, bend the cathode lead (end WITH the stripe) over so it makes

good physical contact with the header pin sticking up through the hole

marked Vin. Trim this lead, then solder this lead to the pin.

This mod lets you run the RGB driver board from an external 12 VDC

supply, but still connect to USB so you can push down new firmware.

Depending on the regulator you install, you may not need an extra

Schottky diode between the power source and the 12 VDC input to the

board. I used a 7805-style regulator I pulled from a defunct

board, and I noticed my RGB board was feeding 5 VDC back into my bench

supply if I had the bench supply off and the T31 powered by USB.

Setting up the timers

There really isn't much to this code. The hardest part is

initializing the FTM timers to provide selected PWM pulses. Here

is the my initialization code::

/*

*

PWMInit configure PWM channels

*

* This routine sets

up the PWM channels used for RGB control. The

* PWM channels are

all configured for legacy mode (none of the second

* set of FTM

registers [starting with FTMn_MODE] are used).

*

* FTMn_CNT sets the

PWM initial value; this must be 0 for edge-aligned

* PWM mode.

This value will be the same for all PWM channels.

*

* FTMn_MOD sets the

PWM modulus (overflow) value. This valuw will

* be the same for all

PWM channels.

*

* Each channel has

its own output-compare match value, in register

* FTMn_CxV. The

value written to this register must be

* FTMn_CNT >=

value < FTMn_MOD. The value written to this register

* sets the duty cycle

of the PWM waveform.

*/

static void PWMInit(void)

{

SIM_SCGC6 |=

SIM_SCGC6_FTM0_MASK; // enable the

FTM0 subsystem clock

SIM_SCGC6 |=

SIM_SCGC6_FTM1_MASK; // enable the

FTM1 subsystem clock

SIM_SCGC3 |=

SIM_SCGC3_FTM2_MASK; // enable the

FTM2 subsystem clock

FTM0_SC =

FTM_SC_CLKS(1) | FTM_SC_PS(2); // use system clock,

select divider

FTM1_SC =

FTM_SC_CLKS(1) | FTM_SC_PS(2); // use system clock,

select divider

FTM2_SC =

FTM_SC_CLKS(1) | FTM_SC_PS(2); // use system clock,

select divider

/*

* Configure each PWM

driver line for active-low operation.

* Use edge-aligned

PWM; clear output when initial value is loaded, set output

* on match.

*

* Configure each port

line for FTM, high drive strength, totem-pole output.

*/

PORTC_PCR1 =

PORT_PCR_MUX(0x4); // red.0 is on

PTC1 (Teensy pin 22); FTM0 ch 0 (alt = 4)

FTM0_C0SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTC_PCR2 =

PORT_PCR_MUX(0x4);

// green.0 is on PTC2 (Teensy pin 23); FTM0 ch 1

(alt = 4)

FTM0_C1SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTC_PCR3 =

PORT_PCR_MUX(0x4);

// blue.0 is on PTC3 (Teensy pin 9); FTM0 ch 2 (alt

= 4)

FTM0_C2SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTC_PCR4 =

PORT_PCR_MUX(0x4);

// red.1 is on PTC4 (Teensy pin 10); FTM0 ch 3 (alt

= 4)

FTM0_C3SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTD_PCR4 =

PORT_PCR_MUX(0x4);

// green.1 is on PTD4 (Teensy pin 6); FTM0 ch 4 (alt

= 4)

FTM0_C4SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTD_PCR5 =

PORT_PCR_MUX(0x4);

// blue.1 is on PTD5 (Teensy pin 20); FTM0 ch 5 (alt

= 4)

FTM0_C5SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTD_PCR6 =

PORT_PCR_MUX(0x4);

// red.2 is on PTD6 (Teensy pin 21); FTM0 ch 6 (alt

= 4)

FTM0_C6SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTD_PCR7 =

PORT_PCR_MUX(0x4);

// green.2 is on PTD7 (Teensy pin 5); FTM0 ch 4 (alt

= 4)

FTM0_C7SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTA_PCR12 =

PORT_PCR_MUX(0x3); // blue.2 is on

PTA12 (Teensy pin 3); FTM1 ch 0 (alt = 3)

FTM1_C0SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTA_PCR13 =

PORT_PCR_MUX(0x3);

// red.3 is on PTA13 (Teensy pin 4); FTM1 ch 1 (alt

= 3)

FTM1_C1SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTB_PCR18 =

PORT_PCR_MUX(0x3);

// green.3 is on PTB18 (Teensy pin 32); FTM2 ch 0

(alt = 3)

FTM2_C0SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

PORTB_PCR19 =

PORT_PCR_MUX(0x3); // blue.3 is on

PTB19 (Teensy pin 25); FTM2 ch 1 (alt = 3)

FTM2_C1SC =

FTM_CnSC_MSB_MASK + EDGE_MASK; // Edge-aligned PWM,

assign output on match

FTM0_CNTIN =

0;

// initial value of PWM counter range is always 0

FTM0_CNT =

0;

// any write to CNT copies CNTIN to the counter;

// always init CNT before initing MOD!

FTM0_MOD =

MAX_PWM_COUNT;

// upper limit of PWM counter range is always max

resolution

FTM1_CNTIN =

0;

// initial value of PWM counter range is always 0

FTM1_CNT =

0;

// any write to CNT copies CNTIN to the counter;

// always init CNT before initing MOD!

FTM1_MOD =

MAX_PWM_COUNT;

// upper limit of PWM counter range is always max

resolution

FTM2_CNTIN =

0;

// initial value of PWM counter range is always 0

FTM2_CNT =

0;

// any write to CNT copies CNTIN to the counter;

// always init CNT before initing MOD!

FTM2_MOD =

MAX_PWM_COUNT;

// upper limit of PWM counter range is always max

resolution

}

The code is straightforward. MAX_PWM_COUNT is the upper limit to

the FTM channel and corresponds to 100% on. This value is defned

elsewhere in my system and is currently 4000.

EDGE_MASK is a named literal that defines the value written to a FTM

CnSC register, and is an OR-mask of two bits ELSnB:ELSnA. Because

I've configured the FTM channels for edge-aligned PWM, I can use either

of two values for EDGE_MASK. A binary value of 0b10 defines the

channel as active-high; pulses start out high at timer value 0, then go

low when the timer value matches the count value. A binary value

of 0b01 defines the channel as active-low; pulses start out low at

timer value 0, then go high when the timer value matches the count

value.

To change the duty cycle of a PWM channel, and hence the brightness of

the associated LEDs, simply write a new value to the FTM channel's CnV

register. For example, the red LEDs in the second RGB strip are

controlled by FTM0_C3V. Writing a value between 0 and

MAX_PWM_COUNT to FTM0_C3V will immediately change the duty cycle of

that set of LEDs.

This is an admittedly light overview of the FTM subsystem.

Download a copy of the Freescale K20 Reference Manual and dig through

the section on the Flex Timer Module, using my code as a

reference. Hopefully, that will clear up how to use the FTM for

PWM control.

The software

I've included the C source for this program in this zip file. Note that you will NOT be able

to rebuild this code and try it out, because it requires header files

and object modules that are common to my other programs. However,

you can load the included binary file to your T31 and play around with

changing the colors of the LEDs. You will need to provide a

serial connection (115,200 baud, 8N1) to your PC from the UART

connector at SL4. Since these signals are logic-level, you will

need to provide suitable level-shifting if you want to use a true

RS-232 connection.

The interface is very basic. It uses ANSI control sequences to

clear the screen and move a large highlight block around. The

highlight block selects one RGB strip for each of 20 possible color

scenes. Within the highlighted colors, you can press keys to

change the color intensity:

q increments red value by 1

Q increments red value by 20

a decrements red value by 1

A decrements red value by 20

w, W, s, and S perform the same function for the green value

e, E, d, and D perform the same function for the blue value

Use the keyboard's arrow keys to move the highlight block around on the

screen. For this interface to work, you need to use a VT-100 or

equivalent ANSI terminal emulator, such as TeraTerm.

Note that there is no way (yet) to save any of the changed

colors. There is support for a kind of psuedo-EEPROM on the MK20

device, but I have not added that code yet.

I have added code to try and correct for your eyes' non-linearity

versus PWM duty cycle. The adjustment is a simple one, but I like

the results. If you ask for a PWM value of 2000, which should be

50% brightness, the LEDs appear to be half of full-brightness.

Check the code in the ScaleBrightness() function for details.

Making a board

This is the first project I have taken to a PWB in a long time. I

use the free Eagle board package from CADSoft USA and the difficulty of

converting the Eagle .brd file into a full set of Gerbers for use by a

board house has been more trouble than it was worth. But Sam

needed a board to play with and I needed a board for further code

development, so I had no choice.

I decided to give OSH Park a try

and was very impressed with the results, pricing, and response.

This was my first design to include soldermask and silk-screen and I

love the results. I got three copies of the board (3.5 x 4

inches) for about $60 with free shipping. The feature I like best

about OSH Park, however, is their ability to accept an Eagle .brd file

as input. No need to create Gerbers, just load the .brd file onto

their website, visually check the resulting layers, and place the

order. Wonderful! I will definitely be using OSH Park for

my future projects.

Summary

I am placing the schematic and the code in the above zip file into the

public domain. I want others to take this project and build on

it. This could easily be turned into a marketable product for

large-scale RGB LED lighting control.

Sam is ready to do some commercial pieces using this board, but my

version of the board is far from a commercial product. I write

firmware, I'm not an EE. I haven't addressed any of the many

concerns or requirements that a commercial product must meet before

shipping. I have done no work on flammability, current limits,

EMI, vibration, power supply quality, or thermal. I have no

experience designing a board for manufacturability or testing a product

for regulatory approval. I will leave that to others more

qualified than I.

You are welcome to use this project as a starting point, and you do so

at your own risk and with full responsibility for the results.

The design you see here is at best a proof of concept and far from

ready for commercial use, but it's got a lot of potential.

Home