| Configuration |

Current,

with

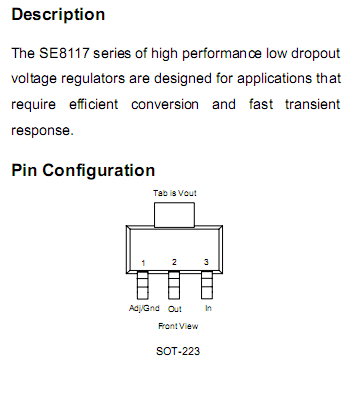

SE8117 |

Current,

with

Pololu

reg |

| Baseline |

410 mA |

360 mA |

| Baseline, Teensy++ USB kbd off |

368 mA |

312 mA |

| Baseline, Ethernet disconnected |

360 mA |

312 mA |

| Baseline, no-name USB mouse

connected |

442 mA |

396 mA |